|

MeltLab for Aluminum |

|

MeltLab for Aluminum is a multi-generational improvement over the AluDelta product now marketed by Sidermess with

detection and quantification for inoculation and modification in the entry level "basic" version, detection of beta crystal,

copper and magnesium silicide structures in the "advanced" version, and, coming soon, direct measurment of the percent beta,

copper and magsilicide phases by energy integration. (See our paper in the AFS Casting Congress in 2011).

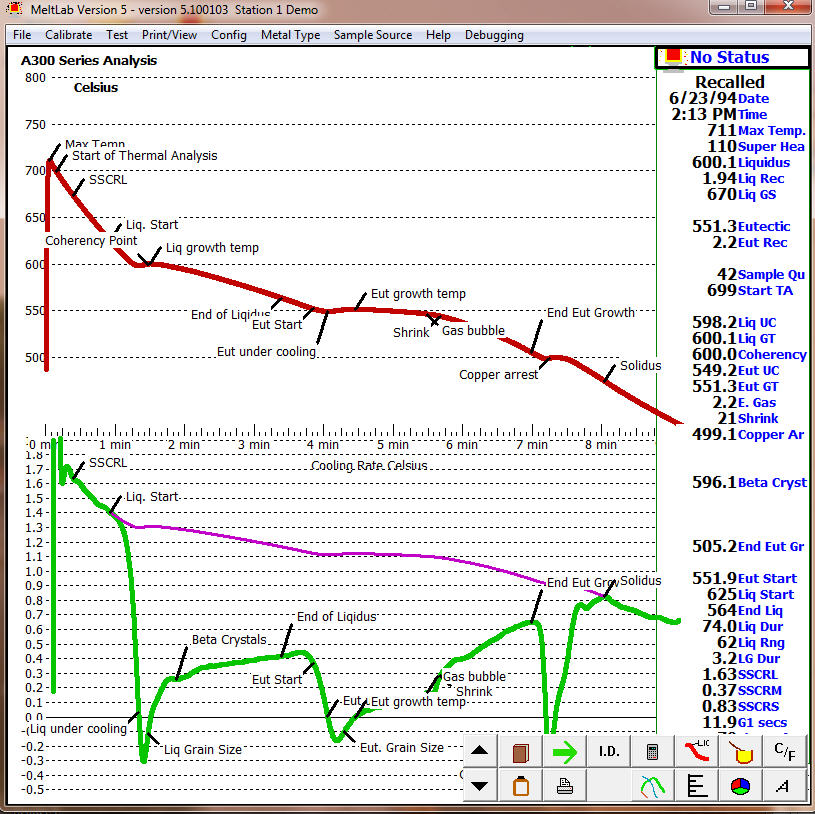

Using powerful smoothing techniques and 4th, and 5th derivative analysis unavailable to our competitors, we have nailed the science of thermal analysis. These methods have been applied to A319 and A355, A356 alloys, but can be applied to other alloys as well. The graphic below is busy with many arrests, but you can pick and choose what is shown through the curve editor. The system automatically preserves the last 100 analysis for each station, but you also have a 2000 per year archive to save curves into for later recall, and the results from the curve can be immediately sent to a file on the network for reporting or reading by Microsoft's Excel, or imported into a data base (tab delimited file). |