|

MeltLab for Ductile Iron

|

|

|

|

MeltLab for Ductile Iron Microstructure makes use of some original research as well as practical metallurgy. First we start

with determining the freezing mode: hypoeutectic, eutectic or hypereutectic. We discovered that occasionally, a hypereutectic

iron can degrade into a hypoeutectic iron because too much graphite came out in the liquid turning the remaining liquid into a

hypoeutectic iron.

Next we used our abilities with high order derivatives to realize the discovery of Dr. Lampic that smooth eutectics mean good

nodularity, and rough ones mean poor nodularity. Next we looked at what Torbjorn Skaland described as the pearlite/ferrite

indicator and came up with a good measurement of this factor.

Shrink was the final characteristic to capture. For that we had to

develop a new theory of how graphite growth and iron volume interact. It was not enough to directly measure a shrink forming, because

a suck-in was shrinkage expressed in a different form, and would not show up in thermal analysis. Instead we realized that it was

natural to form stress during solidification. The graphite that counteracts shrinkage continues to grow after solidification, so at

the solidus only part, 4 to 5% of the volume of the casting, has been replaced with graphite. The remaining volume is grain boundary stress

or shrinkage. So if we measure the grain boundary stress and find it to be high, we have a solid casting. If it is low, the stress has been

relieved by either shrink or suck-in. Then it was just a matter of determining a standard stress and finding a way to get consistent results.

|

|

-

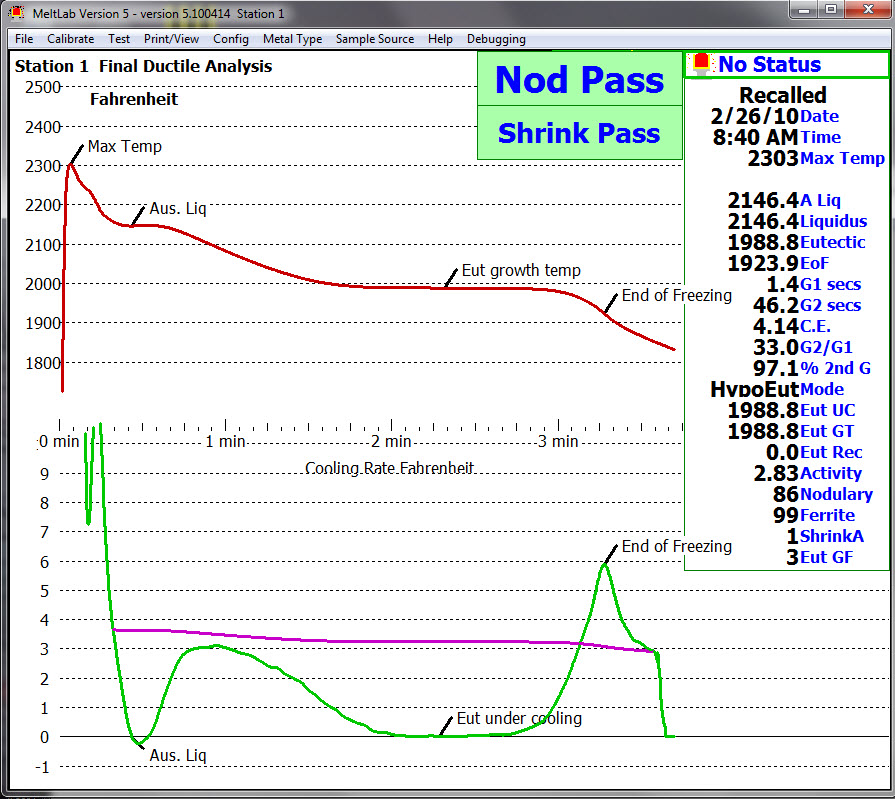

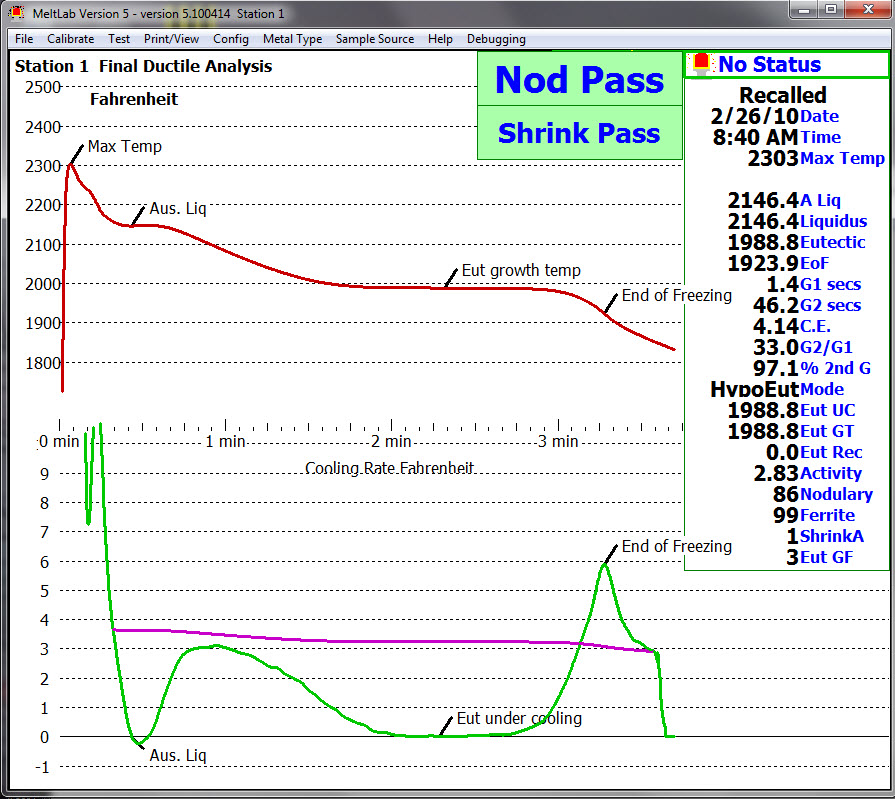

Typical MeltLab Ductile Microstructure Analysis Screen showing temperature curve (red), cooling

rate curve (green) and zero or baseline curve (magenta). Click to enlarge.

|

-

Up to 9 sampling stations.

-

Up to 50 grades of aluminum

-

Select which tests to display, font sizes and colors.

-

Prints results to paper or a file (network capable)

-

Graphs copy and paste into MicroSoft products: Word and Excel

-

View results from anywhere on the network

-

Estimates Ferrite/Pearlite

-

Estimates Nodularity and nodule count

-

Detects shrinkage voids carbides and gas.

-

Measures total shrinkage by residual stress.

|

|

|

|

|

|

|

Copyright © MeltLab Systems Winchester, VA, USA 2014

|

|

|

|

|