The concept of zones of Solidification for Aluminum 356

We know different constituents percolate out at different stages in the solidification process. The energy generation of a phase offsets the cooling of the material and shows up on the cooling curve as discrete zones. There are also small temperature changes that can signal things like Al2Cu2 formation or Mag-Silicide or shrinkage.

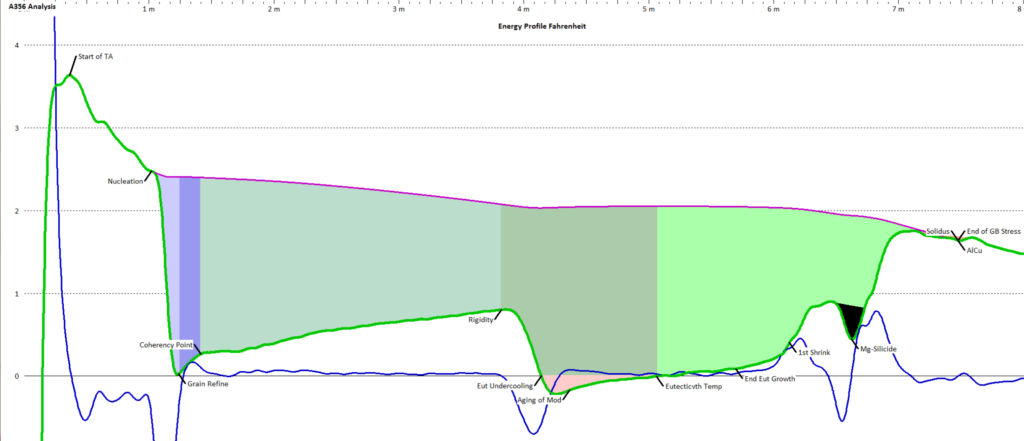

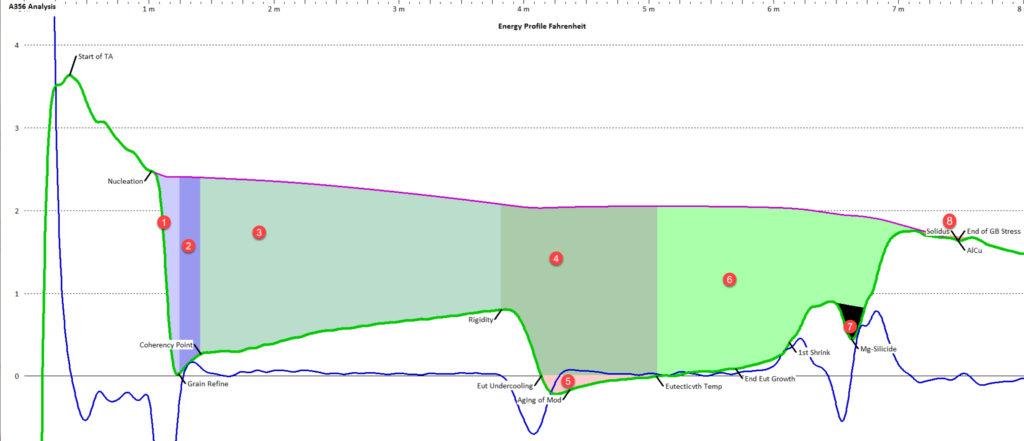

By using physics and metallurgy, these zones can be identified. Using math, these areas can be measured for a better control of our castings. The curve below has 8 major zones of interest. The bumps in the curve in area 3 to the left of the Rigidity point are hydrogen gas or beta and Pi crystals and will be discussed elsewhere. This material has been degassed and grain refined. There is some micro-porosity and shrinkage evident.

- This is the primary liquidus area where dendrites are rapidly growing and includes area 2. This curve is 356 Aluminum, and has been properly grain refined, but not overly refined.

- This is the area of further but slowed dendrite growth until the dendrites grow into each other (coherency point),

- This is the area of dendrite thickening. During this stage both hydrogen gas bubbles form and the iron aluminum phases of Beta and Pi form. This sample looks very good for low gas and low iron.

- This is the main area of eutectic growth and includes area 5. Feeding is still good so shrinkage is postponed.

- This is the area of recalescence and shows information on modification. The area indicates how modified it is. The slope out of the modification shows the aging of the modification. This has been recently and significantly modified.

- This is the later growth of the Aluminum eutectic. During this time feeding becomes restricted, Mag-silicide forms, micro-porosity forms, and we have possible shrinkage voids forming.

- This is the actual Mag-silicide arrest. There are two closely related forms of MgSi so there are sometimes overlapping arrests in this area. Magnesium helps modify or prevent beta crystals

- There is a slight trace of a small copper arrest. It is only at a trace level.

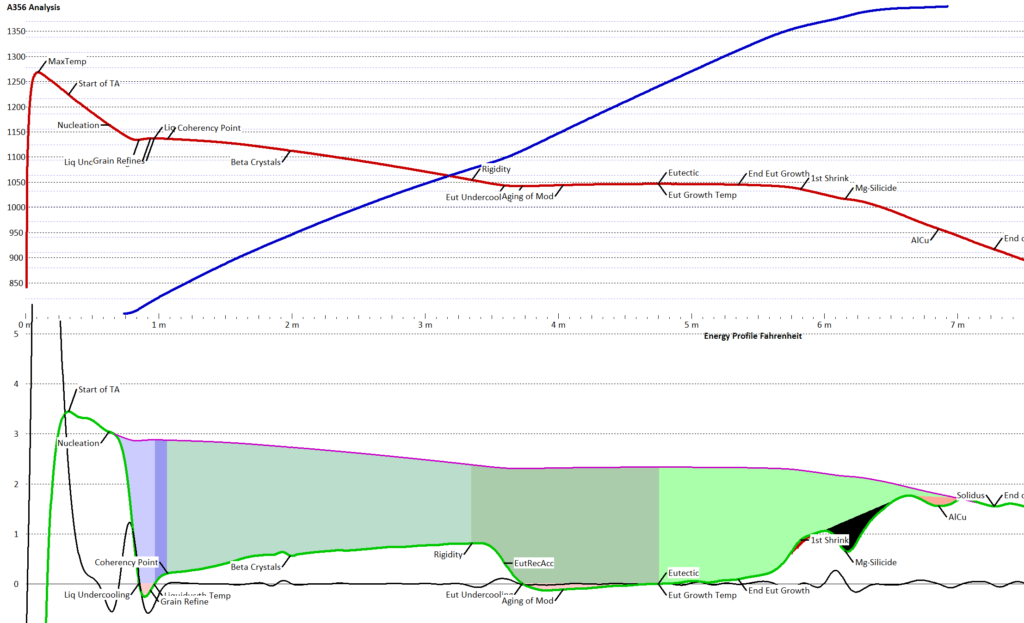

Cooling rate and full curve for 356 type Aluminum

Click HERE to return to Aluminum