The concept of zones of Solidification for White Iron

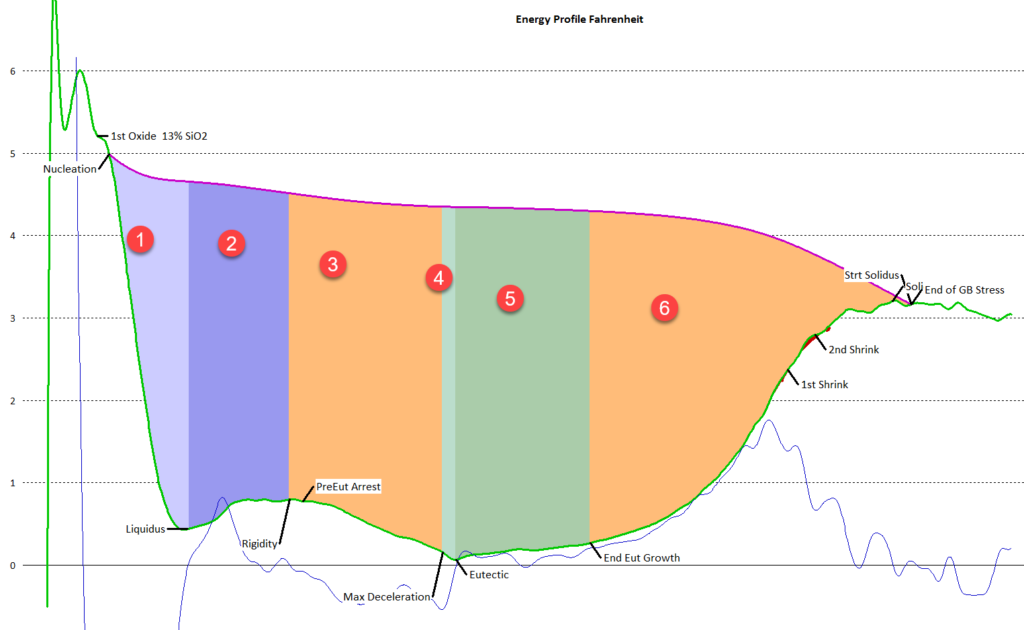

We know different constituents percolate out at different stages in the solidification process. The energy generation of a phase offsets the cooling of the material and shows up on the cooling curve as discrete zones. There are also small temperature changes that can signal things like carbide formation or shrinkage.

By using physics and metallurgy, these zones can be identified. Using math, these areas can be measured for a better control of our castings. The curve below has 7 major zones of interest. The bumps in the curve in area 2 to the left of the Rigidity point are primary carbides and will be discussed elsewhere. White iron is unique in that there is generally less than 2% graphite present. This is accomplished by destroying most of the nuclei for graphite. A major concern for White iron is the generation of carbides and limiting the amount of the softer pearlite. Zone 6 gives us that information.

- This is the early liquidus area where dendrites are rapidly growing. This curve is gray iron, and has no problem nucleating dendrites.

- This is the late liquidus area which is dominated by dendritic branching.

- This is the early eutectic and extends down to the maximum rate of acceleration. This is where the eutectic formation has gained its max acceleration. Because little to no graphite is being formed, this has a much lower and longer heat generation area than other irons.

- This is a very short area and generally is where the graphite grows. The bump at the bottom of this area is energy produced by graphite coupled with austenite growth.

- This is the main eutectic area is where the eutectic energy generation slows down and an equilibrium growth rate dominates. This is mostly pearlite growth. Feeding is still good, and little shrink is evident.

- This area is the last Eutectic. Feeding is now restricted and both shrink and carbides are often found forming in this area. This area increases with the hardness of the finished product.

Click HERE to return to Our Software