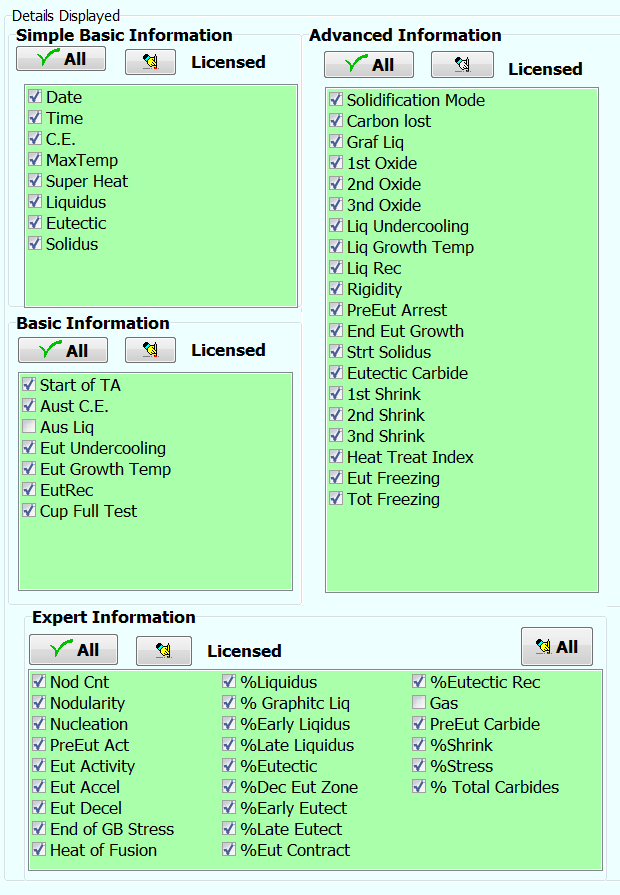

The MeltLab system has a final Ductile Iron (DI) option to improve quality control for the iron going into the mold. The iron is sampled in a plain sample cup after post-inoculant, or, if that is not possible, by using a sample cup that contains a controlled amount of the currently used post-inoculant. The MeltLab then reports mode of freezing, free or available magnesium, nodule count, nodularity, late graphite expansion, and shrinkage, and will also detect and report carbides if present.

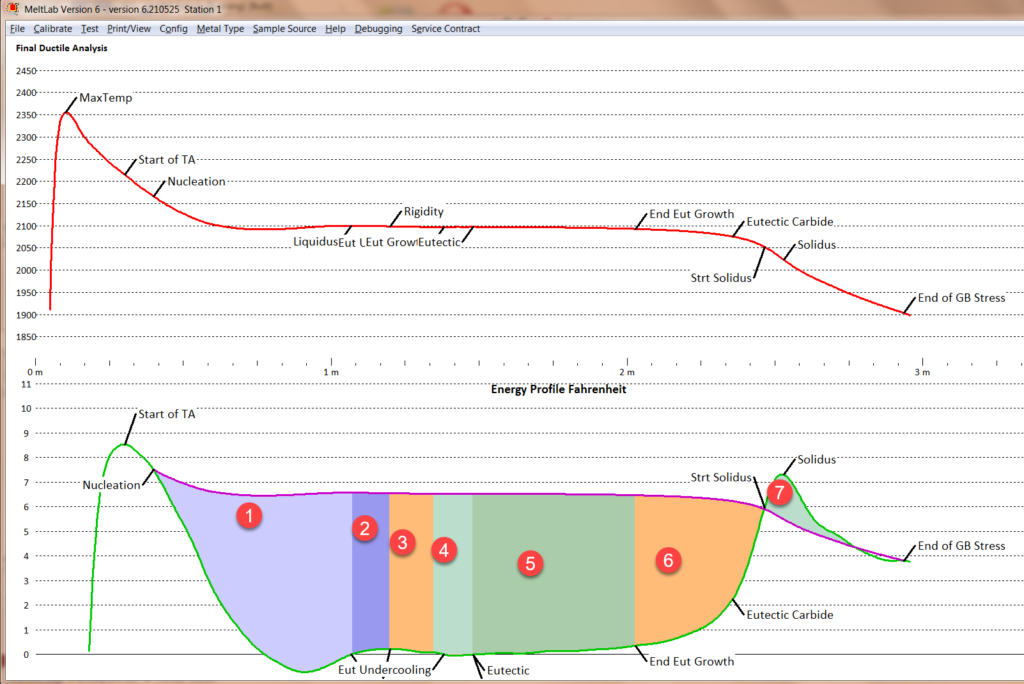

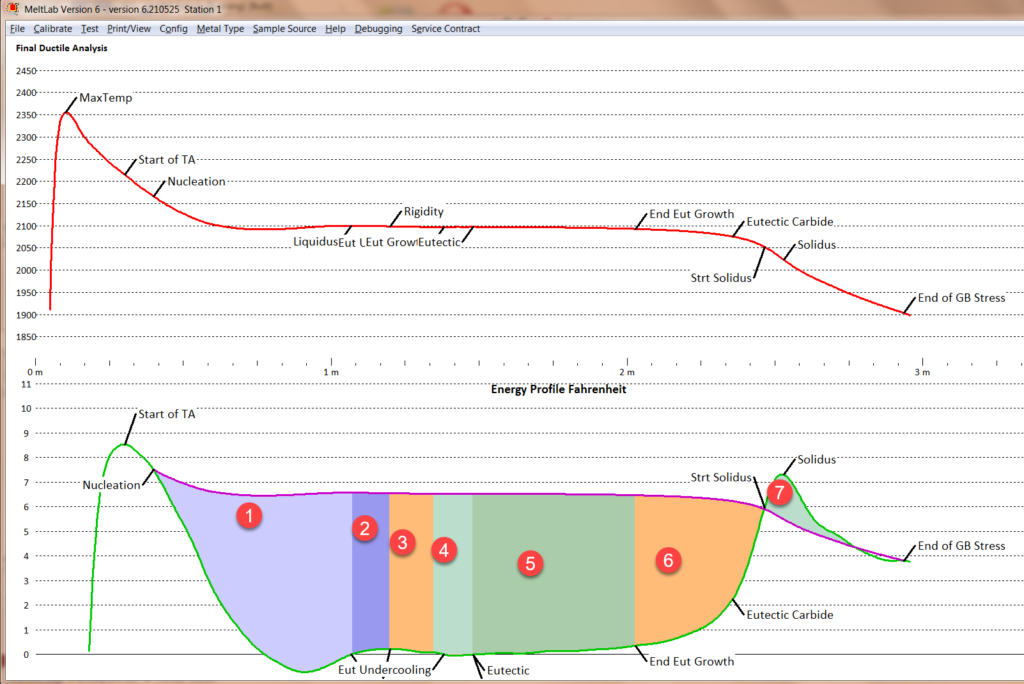

The concept of zones of Solidification for Ductile Iron

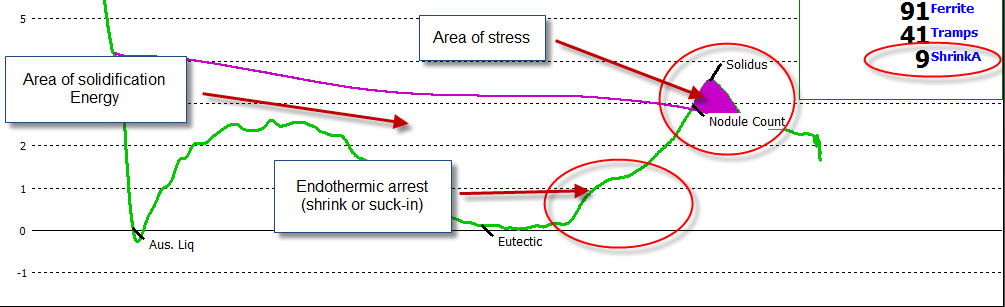

We know different constituents percolate out at different stages in the solidification process. The energy generation of a phase offsets the cooling of the material and shows up on the cooling curve as discrete zones. There are also small temperature changes that can signal things like carbide formation or shrinkage.

By using physics and metallurgy, these zones can be identified. Using math, these areas can be measured for a better control of our castings. The above curve has 7 major zones of interest. Bumps in the curve in area 1 sometimes appear and seem to be early graphite formation and will be discussed elsewhere.

This curve would typically be called “Eutectic” even though there are two distinct growth areas about 2 degrees F apart and should be called hypo-eutectic. Magnesium strongly affects the liquidus and pushes it downward.

- This is the liquidus area where dendrites. The undercooling is due to the magnesium content destroying the seed crystals that nucleate dendrites.

- This is the late liquidus area which is dominated by dendritic thickening.

- This is the early eutectic and extends down to the maximum rate of acceleration. This is where the eutectic formation has gained its max acceleration. Unlike Gray Iron, the slope is very gentle.

- This is the area where recalesence can happen. Highly inoculated Ductile Iron will have little to no recalesence. Lesser inoculated irons or hypo-eutectic irons will show more undercooling and so more recalesence. Iron classifications need to take into account the wall thickness to judge how much inoculation is needed. Calculations of nodule count based on speed of recalesence will fail with no recalesence, but the nodule count here is fine.

- This is the main area of eutectic growth and where nodularity growth happens. Vermicular growth happens late in this zone if the magnesium drops too low. It too has a unique signature discussed in the CGI thermal analysis.

- This area is the last Eutectic. Feeding is now restricted and both shrink and carbides are often found forming in this area.

- This is the grain boundary stress area where more is better. Stresses which do not result in shrink or micro-porosity go into grain boundary stress. The late graphite growth between solidus and eutectoid will tighten up the loose grain boundaries and remove this stress. It is better to have this area then to have shrinkage or micro-porosity. The more of this area is present, the less you will have of the other.

MeltLab looks for hypoeutectic and hypereutectic arrests before the eutectic. The presence of either of these arrests indicates that a lower amount of carbon will be available to form late graphite.

DI MeltLab can be used to drastically reduce the need for micro and chemistry sampling, and provide quicker results than either method. We recommend twice a shift confirmation tests, as well as tests anytime the iron falls outside of control limits. In addition, DI MeltLab provides a clear picture of the effectiveness of different inoculants, and shows when high magnesium can start causing shrinkage problems.

Click HERE to return to Our Software