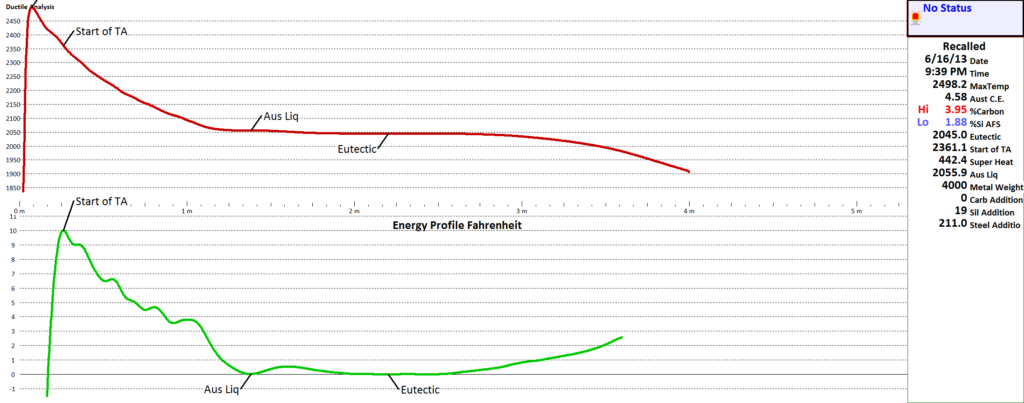

MeltLab for iron chemistry performs the traditional tasks of measuring CE Carbon, Silicon, Liquidus and Eutectic. We were also the first to add the End of Freezing arrest, also known as Solidus. What makes MeltLab different is uncompromising accuracy and precision.

The difference between MeltLab and other systems available can be seen in our warranty. We offer a 10 year warranty on our systems, while our competitors only offer 12 month warranties. Our quality and precision surpasses other systems, and that is reflected in our warranty.

This comes in two levels and works for all grades of gray, ductile, cg iron, white iron and malleable. Phosphorus calculations are provided for foundries in aluminum smelters that wish to control their phosphorus levels.

Click on the level below to view the options available for testing:

We were the first to introduce a computer based thermal analysis system for foundry production. We also introduced a high precision analog to digital converter, data smoothing to obtain 0.05 degree precision and 0.1 degree accuracy as well as the first to introduce corrections for wire bias, and the first to detect oxidized iron by thermal analysis.

- Up to 9 sampling stations

- Up to 50 grades of iron

- Select which tests to display, font sizes, and colors

- Charge additions/Charge corrections calculated

- Oxide detection available

- Fine tuning for silicon calculation

- Prints results to paper or a file (network capable)

- Graphs copy and paste into Microsoft products (Word and Excel)

- View results from anywhere on the network

- Supports up to 10 temperature lances

Click HERE to return to Our Software