The Advanced level is for sophisticated foundries needing additional controls and includes all the tests in the previous levels. Heat treating can be shortened if the chemistry is right or lengthened if it is wrong. Austempered irons require controlling the Heat Treat index for strength and consistency in the heat treatment. Refining the nucleation of Austenite is an area few offer but we present it. And finally, oxide arrests indicate how effective your inoculation will be or how your magnesium recovery will be affected.

Malleable requires a bit of skill to measure the iron at a high enough temperature to see the liquidus at about 2300 F and not melt the thermal couple at 2540 F. A skilled furnace operator can tell by the “color” of the iron when the temperature is right to pour the cup.

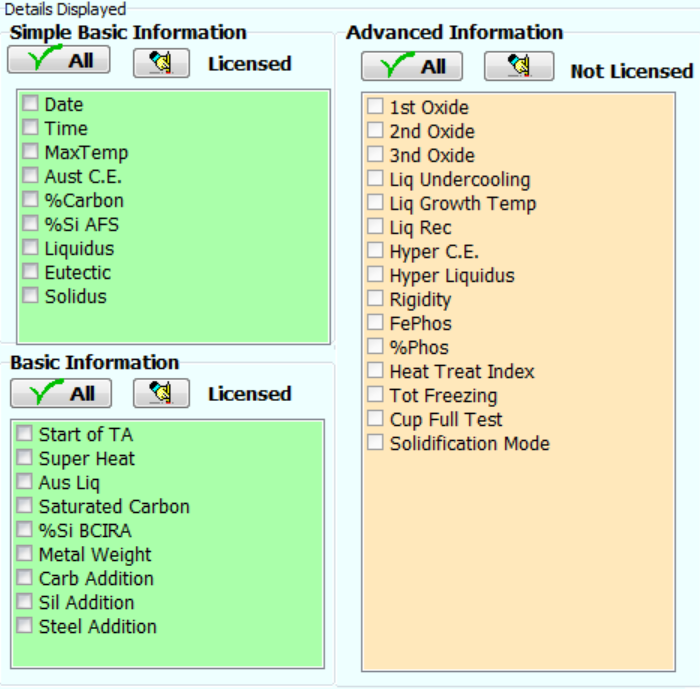

Using the options:

By checking a test, you control the reporting of that test to the screen. You may not want to put too many tests up for the operator to consider. But there is a second option list in the reporting system. Here you can choose to report some or all of the tests to a CSV file for your records for in depth analysis.

Click HERE to return to Iron Chemistry